-

-

Integrated equipment

-

Hydrocyclone cluster

-

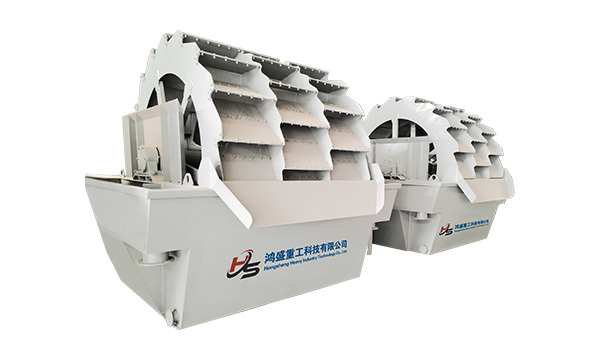

Wheel-Type Integrated Sand Washing and Recycling Machine

-

Spiral Sand Washing and Recovery Integrated Machine

-

UTE integrated sand-washing and recovery machine

View More -

-

Screening equipment

-

Shaftless Trommel Screen

-

Circular vibrating screen

-

Banana-Type Constant Thickness Screen

-

Three-axis elliptical vibrating screen

-

Linear Vibrating Screen (Dewatering/Grading Type)

-

Double layer linear sieve

-

Flip-Flow Screen

View More -

-

Cleaning equipment

View More -

Fine sand recycling equipment

View More -

Sewage treatment equipment

-

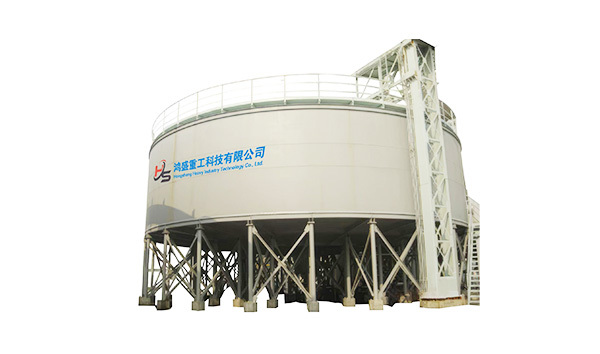

Radial Flow Thickener

-

High-Pressure Diaphragm Chamber Filter Press

-

Deep Cone Thickener

-

Chamber Filter Press

-

Belt filter press

-

Flocculant automatic dosing systems

View More -

-

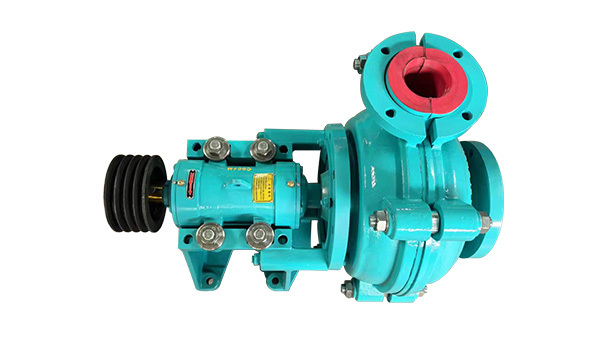

Spare parts

View More

-

Application of Thickeners in the Mining and Mineral Processing Industry

Sep 18,2025

Concentrate Dewatering:

To dewater low-density concentrate slurries (typically with a moisture content exceeding 80%) produced from flotation or other beneficiation methods into high-density slurries (typically with a moisture content of 30–50%), preparing them for subsequent filtration, drying, and smelting processes. Examples include copper concentrate, iron concentrate, and gold concentrate.

Tailings Management:

To thicken discarded tailings slurries after mineral processing, enabling efficient water recovery (overflow water is recycled, conserving water resources) and dry stacking (high-density underflow is transported to tailings storage facilities, enhancing safety and reducing environmental pollution).

High Throughput:

Especially in tailings thickening applications, thickeners are often required to handle the entire processing capacity of the plant, resulting in massive scales (with diameters exceeding 100 meters).

Abrasion Resistance:

The solid particles in slurries are typically hard and sharply angular, demanding extremely high abrasion resistance in the feed system, rake arms, rake teeth, and underflow pumps. This is achieved using ultra-high-molecular-weight polyethylene (UHMWPE) plates, specialized wear-resistant steel, or ceramic linings.

High Compressibility:

Powerful rake drive systems (with high torque) are essential to overcome the high friction forces exerted by solid particles in the compression zone, preventing "rake bogging" incidents.

Flocculant Addition and Mixing:

Modern high-efficiency thickeners heavily rely on flocculants to accelerate the settling of fine particles. This requires professional flocculant preparation and dosing systems, along with efficient and gentle mixing with the slurry within the feed well.

Automated Control:

Automated control of underflow pump frequency and flocculant dosage is necessary, based on sensors such as underflow density meters, mud bed level detectors, and torque monitors, to ensure stable operation.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:info@hszgtech.cn

WhatsApp:+86 19838996250

Tel:+8619838996250

Tel:+8618625415217

Address: North end of Hong Kong Road, Xiaoji Town, Xinxiang County, Xinxiang City, Henan Province

REQUEST QUOTE

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页