Share to

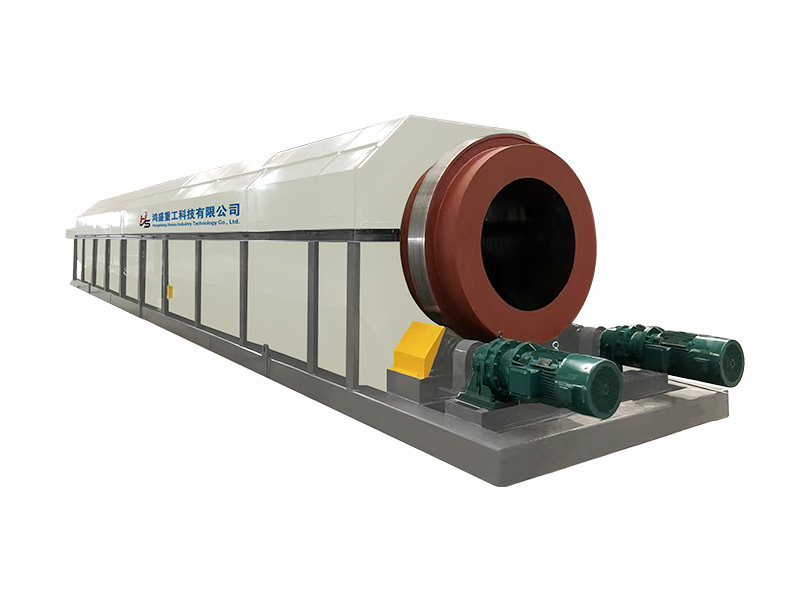

Shaftless Trommel Screen

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

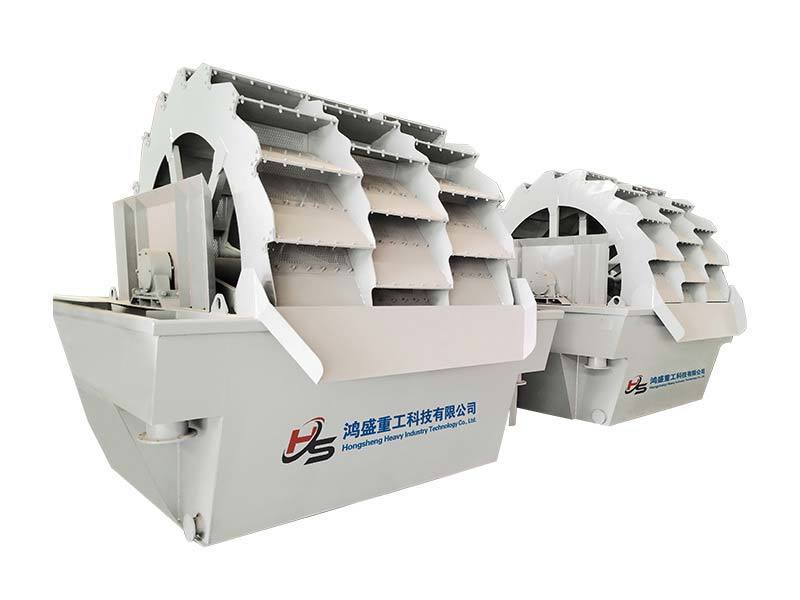

The shaftless trommel screen is a highly efficient and reliable solid material screening equipment, widely used in scenarios such as particle classification, impurity separation, and material filtration. Its core feature lies in abandoning the central shaft structure of traditional trommel screens, adopting an open shaftless design where the screening drum is directly driven by annular support wheels to rotate. This configuration results in a simpler structure and higher screen utilization rate. The screening drum is typically constructed from wear-resistant metal mesh or perforated plates, and can be designed in cylindrical, conical, or polygonal shapes to accommodate different material characteristics and operational requirements.

Working principle

1、Feeding & Screening: Material is evenly fed into the trommel screen through the inlet. The drum rotates at a controlled speed driven by an electric motor and gearbox.

2、Graded Screening: As the drum rotates, materials tumble. Particles smaller than the mesh size fall through the screen into the collection hopper below, while larger particles travel axially along the drum to the discharge end.

3、Multi-stage Classification: Multi-level screening is achieved through segmented drum sections equipped with screens of progressively smaller apertures.

4、Discharge Mechanism: The inclined drum (with adjustable tilt angle) facilitates continuous material flow and separation via gravity and centrifugal forces.

Application Industries

1、Mining & Metallurgy: Grading and screening of coal, ores, and aggregates.

2、Construction Waste Recycling: Classification of recycled aggregates from crushed concrete and bricks.

3、Environmental Protection: Sorting and resource recovery of municipal waste, organic compost, and industrial solid waste.

4、Agriculture: Impurity removal and particle grading of grains (e.g., wheat, corn).

5、Chemical & Power Industries: Particle size control for chemical raw materials and biomass fuels (e.g., wood chips, straw).

6、Aggregate Production: Grading and pre-washing of manufactured sand and crushed stone.

Performance Features & Advantages:

1、Anti-clogging: No central shaft obstruction enables enhanced material flow for viscous/moist materials, minimizing screen blockage risks.

2、High processing capacity: Screen effective area increased by over 30%, ideal for high-throughput applications.

3、Low maintenance: Simplified structure with fewer failure points ensures stable operation and reduced upkeep costs.

4、Efficient screening: Material fully tumbles in the drum, achieving ≥90% screening efficiency (especially for fine particles). Supports dry screening and wet screening (with spray) modes for diverse conditions.

5、Strong adaptability: Handles materials with high moisture content orsubstances (e.g., sludge, wet sand).

6、Customizable screen apertures: 1mm–200mm specifications available to meet varied particle sizing needs.

7、Energy-saving & eco-friendly: Low motor power (typically 5.5–30kW); energy consumption is only 60%–70% of vibrating screens. Sealed design reduces dust emissions, complying with environmental standards.

8、Durability: Wear-resistant screen mesh materials (high-manganese steel, polyurethane) ensure long service life and easy replacement. Support rollers equipped with heavy-duty bearings enable robust load-bearing for continuous operation.

Technical Specifications Table

Equipment Model

Feed Particle Size(mm)

Processing Capacity(t/h)

Drum Specifications(mm)

Drum Inclination Angle(°)

Power

(kw)Overall Dimensions

(mm)HGT1040

≤50

30-60

1000X4000

6

3kw

5500X1460X2340

HGT1240

≤50

30-100

1200X4000

6

5.5kw

5500X1680X2480

HGT1560

≤100

30-150

1500X6000

6

7.5kw

6800X2100X4400

HGT1860

≤100

30-200

1800X6000

6

11kw

8490X2400X4680

HGT2160

≤100

30-250

2100X6000

6

15kw

8490X2760X5000

HGT2460

≤100

30-250

2400X6000

6

18.5kw

8490X3020X5200

HGT2480

≤100

30-300

2400X8000

5-10

22kw

8700X2860X5700

HGT3080

≤100

30-400

3000X8000

5-10

37kw

8800X3660X5800

For more detailed technical specifications or application cases, feel free to contact us for further discussion!

Previous: Flip-Flow Screen

Shaftless Trommel Screen

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Shaftless Trommel Screen

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!