Share to

Mineral and Sand Attrition Scrubber

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

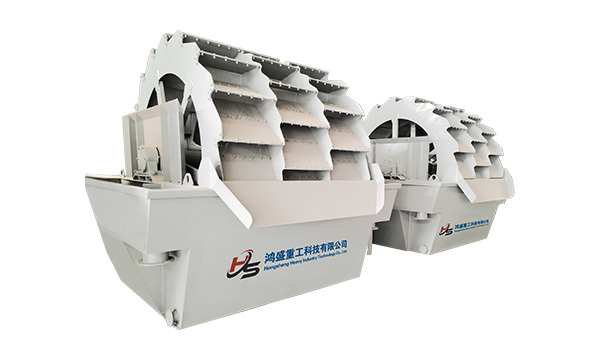

The Mineral and Sand Attrition Scrubber is a high-intensity agitation device designed for concentrated material processing. It is widely used across industries such as metallurgy, chemical engineering, building materials, light industry, food processing, and pharmaceuticals to mechanically abrade material surfaces.

Through vigorous scrubbing and inter-particle friction, this equipment effectively removes surface contaminants, impurities, and oxidation layers, exposing fresh material surfaces. This surface renewal significantly enhances reactivity in downstream processes.

Particularly valuable in mineral processing applications, the scrubber optimizes flotation performance by improving mineral liberation and collector adsorption. Its high-concentration operation mode demonstrates exceptional efficacy in ore pulp treatment, substantially increasing mineral recovery rates in beneficiation operations.

Working principle

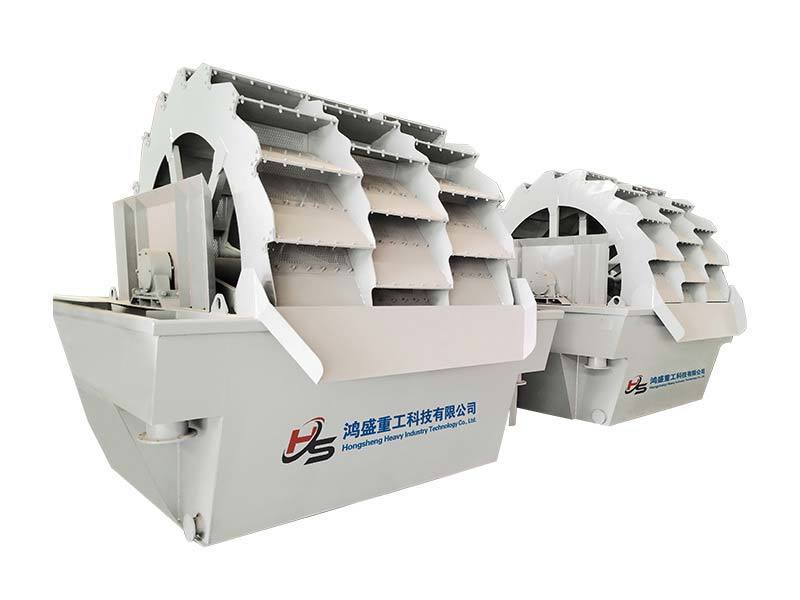

● The machine can be categorized into single-scrubbing chamber, dual-scrubbing chamber, and multi-scrubbing chamber configurations. Each scrubbing chamber is equipped with an independent transmission system, where electric motors drive the main shafts via V-belts to achieve high-speed rotation.

● Each main shaft carries two counter-rotating impellers (angled at 45°) – the upper impeller forces the slurry downward while the lower impeller provides upward thrust. This dual-action creates intense particle collisions between the opposing forces of the impellers, generating powerful friction.

● The polygonal chamber design enhances particle collision opportunities through multidirectional slurry rebound against the walls. Chamber height optimization maintains stable liquid levels by preventing excessive slurry velocity.

● A recirculating scrubbing chamber structure ensures thorough slurry circulation, guaranteeing adequate scrubbing duration while minimizing upward slurry splashing.

Application Industries

Multiple industries including metallurgy, chemical engineering, construction materials, light industry, food processing, pharmaceuticals, and related sectors.

Performance Features & Advantages:

● The product features high-intensity scrubbing and mixing capabilities. With its high material concentration processing capacity and strong inter-material frictional forces, it effectively removes surface-adhering layers, oxide layers, and loose layers from materials, ensuring excellent purification effectiveness.

● Its simple and rational overall design offers a compact footprint while facilitating easy integration with other equipment. The impeller, manufactured from highly wear-resistant materials, ensures long service life and low maintenance costs.

Technical Specifications Table

Equipment Model

Feed Particle Size(mm)

Processing Capacity(t/h)

Chamber Volume (m³)

Impeller Specifications(mm)

Power(kw)

Overall Dimensions(mm)

CX0.5-1

≤5

5-10

0.5

430.0

11.0

2000X980X1800

CX1-1

≤10

10-30

1

480.0

15.0

1180X1150X2060

CX1-2

≤10

10-30

1X2

480X2

30.0

2280X1150X2060

CX2-1

≤10

20-50

2

520.0

30.0

1600X1600X2780

CX2-2

≤10

20-50

2X2

520X2

60.0

3080X1600X2780

CX4-1

≤10

40-80

4

770.0

55.0

1900X1760X3470

CX4-2

≤10

40-80

4X2

770X2

110.0

3720X1760X3470

For more detailed technical specifications or application cases, feel free to contact us for further discussion!

Previous: Spiral Sand Washer

Mineral and Sand Attrition Scrubber

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Mineral and Sand Attrition Scrubber

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!