Share to

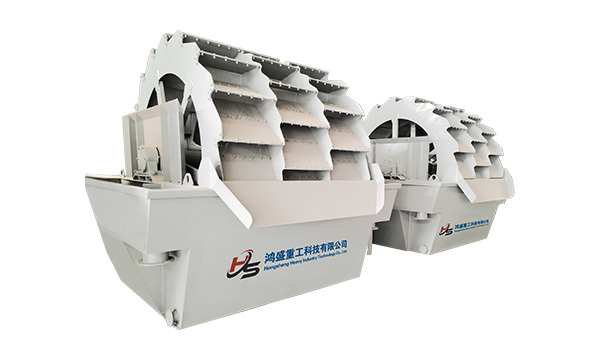

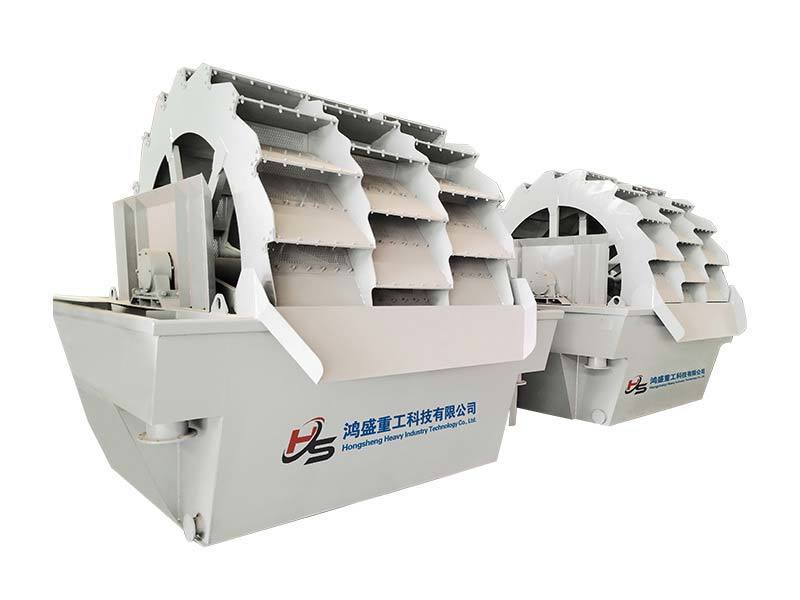

FSR Machine/ FSR&D Integrated Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

Fine Sand Recovery Machine/Integrated Fine Sand Recovery & Dewatering Machine is an environmentally friendly equipment specifically designed for sand processing, mineral processing in mining, and related industries. It is primarily used to recover fine sand particles (below 0.16mm) lost by traditional sand washing machines, thereby reducing resource waste and improving the quality of finished sand. Its core components include a dewatering screen, cyclone separator, motor, slurry pump, etc., and it is designed for integration into wet-process sand production lines.

By leveraging efficient separation technology, the Fine Sand Recovery Machine addresses the critical issue of fine sand loss in traditional sand washing processes. It enhances resource utilization efficiency while meeting environmental protection requirements, making it an indispensable auxiliary equipment in modern sand and gravel production lines.

Working principle

● Slurry Mixing:

● Fine Sand Recovery Machine:

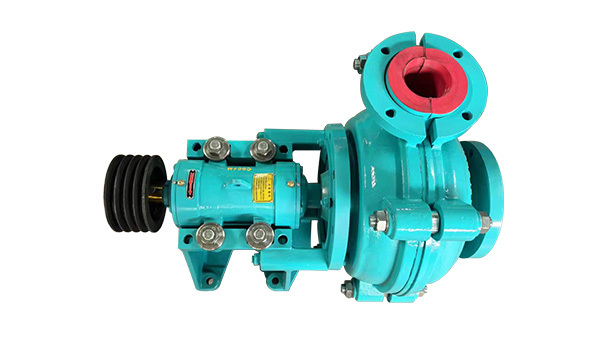

The sand-water mixture is transported to the cyclone separator via the slurry pump.

● Integrated Fine Sand Recovery & Dewatering Machine:

The sand-water mixture first enters the dewatering screen for coarse particle dewatering. The fine particles and water mixture from the screen underflow are then pumped to the cyclone separator.

● Centrifugal Classification:

The cyclone separator utilizes centrifugal force to separate fine sand from muddy water. The fine sand settles at the bottom, while the muddy water is discharged from the top.

● Dewatering & Screening:

The recovered fine sand from the cyclone separator enters the dewatering screen, where high-frequency vibration removes residual moisture, producing dry finished sand.

● Closed-loop Recycling:

The separated muddy water is directed to a subsequent wastewater treatment system, achieving zero liquid discharge (ZLD).

Application Industries

● Sand & Aggregate Processing:Used in mechanized sand production lines to reduce fine sand loss and improve sand gradation.

● Mineral Processing:Recovers valuable mineral particles from mining tailings, minimizing resource wastage.

● Construction Waste Recycling:Extracts fine sand from construction debris for sustainable material reuse.

● River Dredging:Recovers fine sand from silt during dredging operations, improving water quality while reclaiming materials.

Performance Features & Advantages

● High-Efficiency Recovery:Achieves a fine sand recovery rate of over 90%, significantly boosting production output and economic returns.

● Energy-Saving & Eco-Friendly:Utilizes closed-loop water circulation to minimize water consumption and reduce wastewater treatment costs.

● Compact Structure:Features modular design with a small footprint, enabling easy installation and site relocation.

● Smart Control:Fully automated operation with remote monitoring capabilities, reducing manual intervention.

● Exceptional Wear Resistance:Critical components are reinforced with high-chromium alloy or rubber lining, ensuring extended service life.

● High Adaptability:Processes materials with high clay content and complex particle sizes, maintaining stability across diverse operating conditions.

Technical Specifications Table

HS Series Fine Sand Recovery Machine

Equipment Model

Feed Particle Size(mm)

Water Treatment Capacity(t/h)

Screen Plate Specifications(mm)

Hydrocyclone Specifications(mm)

Power(kw)

Overall Dimensions(mm)

HS 250

≤10

20-50

900X1800

250

12.5

3100X1300X2700

HS 300

≤10

40-80

900X1800

300

16.5

3100X1300X2700

HS 350

≤10

60-100

900X1800

350

20

3100X1300X2700

HS 550

≤10

40-100

1200X2400

250X2

26.4

3600X1600X2800

HS 650

≤10

80-160

1200X2400

300X2

34.4

3600X1600X2800

HS 750

≤10

120-200

1200X2400

350X2

41.4

3600X1600X2800

HS 900

≤10

120-250

1500X3000

300X3

51

4600X1900X2600

HS1050

≤10

150-300

1500X3000

350X3

61.5

4600X1900X2600

HS Series Integrated Fine Sand Recovery & Dewatering Machine

Equipment Model

Feed Particle Size(mm)

Water Treatment Capacity(t/h)

Screen Plate Specifications(mm)

Hydrocyclone Specifications(mm)

Power(kw)

Overall Dimensions(mm)

HS1224D-30

≤10

20-40

1200X2400

300

19.4

2760X4850X2780

HS1530D-65

≤10

30-60

1500X3000

300X2

36

3800X5500X3200

HS1842D-75

≤10

40-80

1800X4200

350X2

48

4800X6000X4000

HS1842J-75

≤10

40-80

1800X4200

350X2

52

4800X6000X4000

HS2442J-120

≤10

100-150

2400X4200

300X4

82

4600X6250X3600

HS3048J-140

≤10

120-200

3000X4800

350X4

104

5400X7000X4200

HS3660J-180

≤10

150-250

3600X6000

300X6

134

6600X7000X4800

Next: Cone Classifier

FSR Machine/ FSR&D Integrated Machine

Still deciding? Get samples first, Contact US !

Products Category

Tag list

FSR Machine/ FSR&D Integrated Machine

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!