Share to

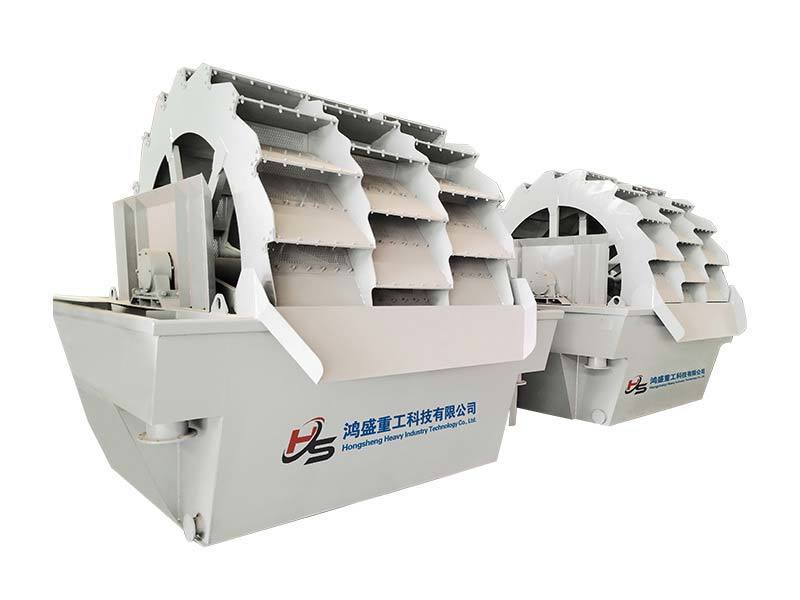

Double Linear Vibrating Screen

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

High-frequency linear vibrating screen is an efficient screening, dewatering, and medium removal equipment primarily used for sorting, grading, dewatering, and medium removal of granular materials. While its design is based on the fundamental principles of linear vibrating screens, it incorporates optimizations in vibration frequency and screening accuracy. This makes it particularly suitable for applications requiring high screening efficiency and precision, while also delivering exceptional performance in dewatering and medium removal operations for both coarse and fine materials. Widely applied across industries including chemical, building materials, metallurgy, pharmaceuticals, food processing, and mining, the high-frequency linear vibrating screen excels in handling large-volume, high-precision screening, dewatering, and medium removal tasks.

Working principle

High-frequency linear vibrating screen operates based on the synchronized counter-rotation of dual vibration motors or exciters:

● Vibration motor/exciter drive:Two synchronized vibration motors or exciters rotate in opposite directions. The excitation forces generated by their eccentric blocks cancel each other in the direction parallel to the motor shafts, while combining into a resultant force perpendicular to the shafts. This mechanism induces linear vibration in the screening machine.

● Material movement:Under the combined action of excitation forces and material gravity, particles are propelled upward and forward in a leap-forward linear motion across the screen surface, thereby realizing screening, grading, dewatering, and medium removal.

Application Industries

● Mining Industry:Applied in screening and grading operations for ores, coal, and other minerals, as well as dewatering and medium removal during mineral processing operations, effectively enhancing ore utilization rates and production efficiency.

● Building Materials Industry:Utilized for screening, dewatering, and medium removal of raw materials including sand, gravel, and cement, ensuring strict compliance with product quality standards.

● Chemical Industry:Employed in screening, dewatering, and medium removal processes for chemical raw materials and powdered substances, precisely controlling particle size and moisture content to meet production process requirements.

Performance Features & Advantages

● High Frequency, Low Amplitude:Vibration frequency reaches 3,000–3,600 vibrations per minute (vpm) (2–3 times higher than conventional screens), ideal for processing fine particles (e.g., 0.074–3 mm), high-viscosity, or low-density materials (e.g., mineral slurry, powders, food additives).

● Rapid Sieving:High-frequency vibration accelerates material stratification, reduces screen clogging, and significantly improves screening efficiency and precision.

● Fine Particle Handling:Specifically designed for ultrafine materials, with a lower screening limit down to 0.038 mm (e.g., metal powders, quartz sand, chemical micro-powders).

● Multi-Layer Grading:Supports 1–3 layers of screen configuration for precise multi-level particle classification (e.g., dewatering, desliming, and grading in mineral processing).

● Vibrator Design:Equipped with high-performance vibration motors or exciters for stronger power and adjustable amplitude to adapt to diverse working conditions.

● Damping System:Spring or rubber damping devices effectively reduce equipment resonance and minimize impact on foundations, extending service life.

● Fully Enclosed Structure:Dust-proof design prevents material splashing, meeting environmental and clean production requirements (e.g., food and pharmaceutical industries).

● Upgraded Screen Materials:Utilizes high-tension stainless steel screens or polyurethane screen panels for enhanced wear and corrosion resistance, prolonging lifespan.

● Corrosion Resistance:Stainless steel construction for the entire machine or critical components, suitable for corrosive environments (e.g., chemical and metallurgical industries).

● High-Moisture Material Handling:Designed for wet screening of high-humidity materials like slurry and sludge (e.g., mineral dewatering and tailings recovery).

● Low Energy Consumption:Optimized motor power configuration reduces energy consumption per unit of processing capacity.

● Smart Control:Integrated frequency converter for adjustable vibration frequency and real-time monitoring of operating parameters (e.g., temperature, amplitude), enabling automated control.

● Modular Screen Frame:Screen replacement without disassembling the main structure, minimizing downtime.

● Few Wear Parts:Simplified structure with primary maintenance points on screens and springs, lowering maintenance costs.

Technical Specifications Table

TS Series High-frequency Linear Vibrating Screen/Dewatering Screen

Equipment Model

Feed Particle Size(mm)

Processing Capacity(t/h)

Screen Plate Specifications(mm)

Screen Deck Area(m)

Power(kw)

Overall Dimensions(mm)

TS0918

≤10

10-20

900X1800

1.62

0.75X2

1890X1290X1080

TS0924

≤10

10-20

900X2400

2.16

1.1X2

2480X1290X1220

TS1224

≤10

20-40

1200X2400

2.88

2.2X2

2480X1590X1430

TS1230

≤10

20-40

1200X3000

3.6

2.2X2

3080X1590X1500

TS1236

≤10

20-40

1200X3600

4.32

3.0X2

3680X1590X1500

TS1530

≤10

30-60

1500X3000

4.5

3.0X2

3080X1890X1440

TS1536

≤10

30-60

1500X3600

5.4

3.7X2

3680X1890X1450

TS1836

≤10

60-80

1800X3600

6.48

5.5X2

3720X2420X1930

TS1842

≤10

60-80

1800X4200

7.56

5.5X2

4370X2420X2100

ZSD Series High-frequency Linear Vibrating Screen/Dewatering Screen

Equipment Model

Feed Particle Size(mm)

Processing Capacity(t/h)

Screen Plate Specifications(mm)

Screen Deck Area(m)

Power(kw)

Overall Dimensions(mm)

ZSD1530

≤10

30-60

1500X3000

4.5

3X2

3080X2500X1600

ZSD1842

≤10

60-100

1800X4200

7.6

7.5X2

4370X3080X2000

ZSD1848

≤10

60-100

1800X4800

8.6

7.5X2

4790X3065X1960

ZSD2442

≤10

80-150

2400X4200

10.1

11X2

4400X3740X1930

ZSD2448

≤10

80-150

2400X4800

11.5

11X2

5000X3740X1980

ZSD2460

≤10

80-150

2400X6000

14.4

15X2

6420X3910X2050

ZSD3048

≤10

120-200

3000X4800

14.4

15X2

4960X4520X2220

ZSD3060

≤10

120-200

3000X6000

18.0

18.5X2

6160X4520X2220

ZSD3660

≤10

150-250

3600X6000

21.6

22X2

6160X5120X2280

Double Linear Vibrating Screen

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Double Linear Vibrating Screen

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!