Share to

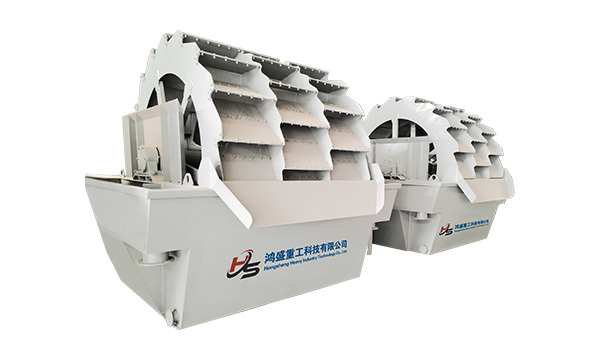

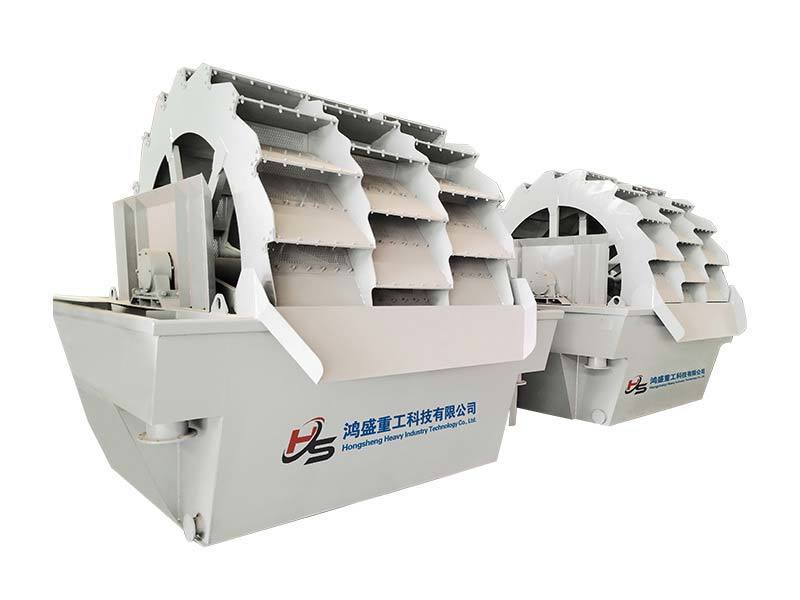

Spiral Sand Washing and Recovery Integrated Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

The spiral sand washing and recovery integrated machine is a highly efficient equipment that combines spiral sand washing, high-frequency linear screen dewatering, and a fine sand recovery system. It is primarily used in sand and gravel aggregate processing, mining, construction waste treatment, and related fields. Its core functions include cleaning sand and gravel through the spiral structure of the sand washer, while simultaneously recovering lost fine sand particles to minimize resource waste and improve both the quality and yield of processed materials.

Working principle

1、Material Feeding:

The sand-gravel mixture is fed into the trough of the spiral sand washer via a feeding device.

2、Spiral Sand Washing:

Spiral blades, driven by a motor, continuously tumble and friction-wash the materials to remove surface mud and impurities. During this process, water flows upward from the bottom of the trough, flushing away light impurities (e.g., mud and dust).

3、Dewatering and Recovery:

The cleaned sand and gravel are lifted by the spiral blades to a dewatering screen for vibratory dewatering, reducing moisture content.

A fine sand recovery system (e.g., hydrocyclones or fine sand recovery machines) further processes wastewater containing fine sand, separating and recycling particles ≥0.075mm.

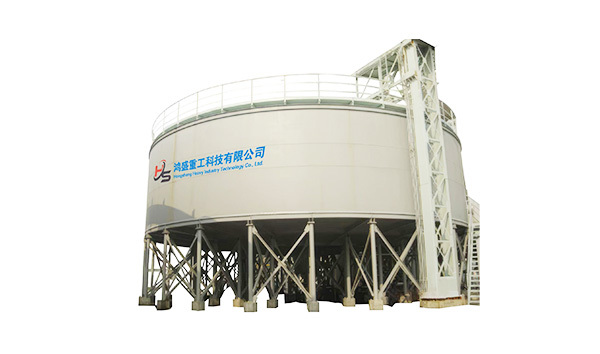

4、Tailwater Treatment:

The wastewater is filtered through settling ponds or a water recycling system for reuse, achieving environmental protection and energy efficiency.Application Industries

1、Sand and Gravel Aggregate Processing:Cleaning natural sand and manufactured sand to enhance the cleanliness and gradation of construction-grade sand.

2、Mining:Processing sand and gravel from tailings (e.g., gold/iron ore) to recover valuable mineral particles.

3、Construction Waste Recycling:Washing recycled aggregates from construction debris for reuse in concrete production.

4、Water Conservancy Projects:River dredging, sand screening, and washing for sediment management.

5、Environmental Protection Industry:Sludge dewatering in wastewater treatment plants and resource utilization of solid waste.Performance Features & Advantages

1. High-Efficiency Washing & Recovery

Optimized spiral blade design ensures strong washing capability, with fine sand recovery rates reaching 85–95%, minimizing resource loss.

2. Energy Saving & Eco-Friendly

Equipped with a water recycling system to reduce water consumption.

Treated wastewater meets environmental standards for discharge.

3. Compact Structure, Small Footprint

Integrated design combines sand washing and recovery functions, saving installation space.

4. Stable Operation & Easy Maintenance

Critical components (e.g., spiral blades, screens) use wear-resistant materials (high-manganese steel, polyurethane).

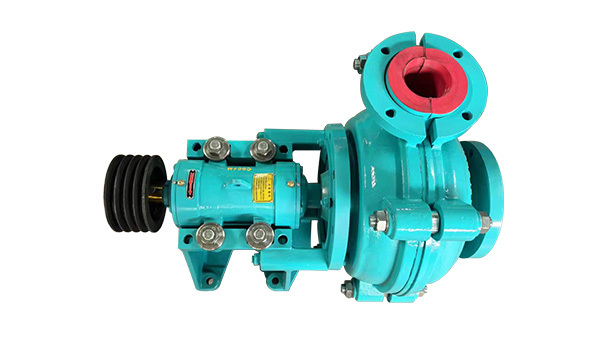

Slurry pump flow parts adopt Cr26 wear-resistant steel, ceramics, or rubber for extended service life.

Modular design simplifies maintenance.

5. Strong Adaptability

Handles materials with high mud content and broad particle sizes (0.075–10mm), suitable for complex working conditions.

6. Automated Control

Supports PLC-based intelligent control for fully automated feeding, washing, and recovery processes, reducing labor costs.Typical Configurations

Core Components: Spiral sand washer, dewatering screen, fine sand recovery system (hydrocyclones + vibrating screen), water pump, settling pond.

Optional Features: Variable frequency speed control, intelligent monitoring system, customized screen apertures.Selection Guidelines

Choose models based on material properties (mud content, particle size).

Match equipment specifications to production capacity requirements.

Prioritize models with wear-resistant materials and intelligent control systems to reduce long-termTechnical Specifications Table

Equipment Model

Feed Particle Size (mm)

Processing Capacity (t/h)

Spiral Blade Diameter(mm)

Screen Specifications (mm)

Power(kw)

Overall Dimensions(mm)

XL07-30-1224D

≤10

20-40

760

1200X2400

26.9

10880X5240X3720

XL09-35-1530D

≤10

30-60

920

1500X3000

35.5

11490X5560X3960

XL11-65-1842D

≤10

40-80

1120

1800X4200

59.5

12830X5860X4250

XL09-75-1842J

≤10

80-120

920X2

2400X4200

74

12630X6450X3860

XL11-120-2442J

≤10

100-150

1120X2

2400X4200

119

12630X6450X4150

XL15-140-3048J

≤10

100-160

1500X2

3000X4800

148

13560X7860X4300

XL15-180-3660J

≤10

160-250

1500X2

3600X6000

178

14760X7920X4900

For more detailed technical specifications or application cases, feel free to contact us for further discussion!

Previous: Wheel-Type Integrated Sand Washing and Recycling Machine

Spiral Sand Washing and Recovery Integrated Machine

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Spiral Sand Washing and Recovery Integrated Machine

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!