Share to

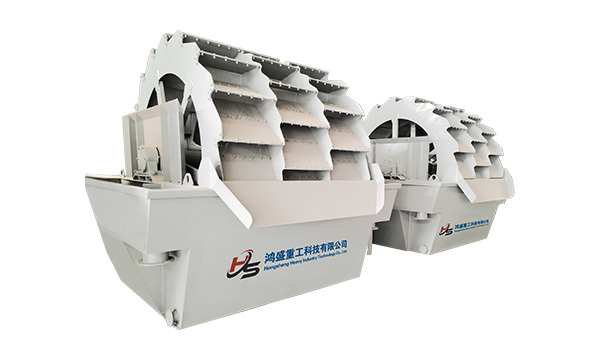

Spiral Sand Washer

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

The spiral sand washer is a piece of equipment designed for cleaning and classifying sand and gravel. It is widely used in industries such as sand and gravel fields, mining, building materials, transportation, chemical engineering, water conservancy and hydropower, and concrete mixing stations. Its primary functions include removing impurities from the surface of sand and gravel, disrupting the water vapor layer coating sand particles, thereby achieving efficient cleaning and dewatering.

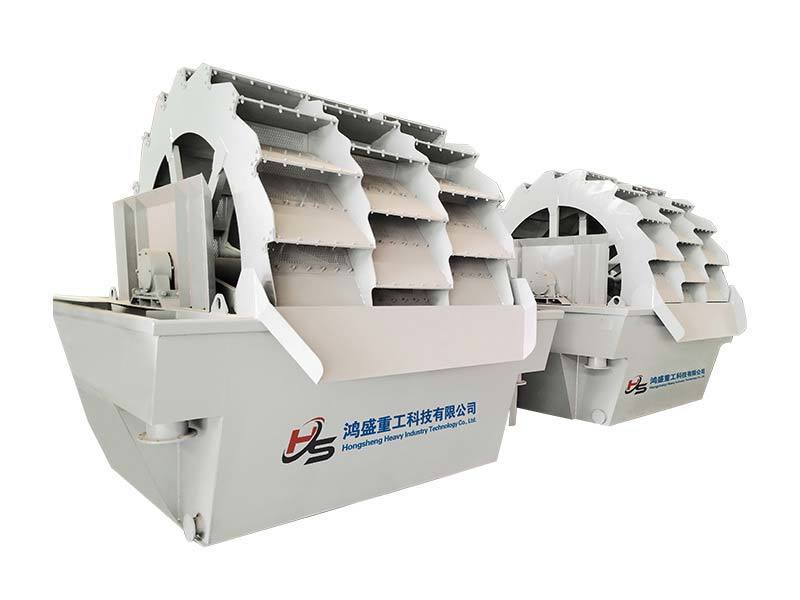

Spiral sand washers are categorized into single-spiral and double-spiral types. Their structure comprises components such as a motor, reducer, spiral blades, water tank, feed inlet, and discharge outlet. Featuring rational design, high processing capacity, low power consumption, and minimal sand loss, this equipment serves as an essential component in modern sand and gravel production lines.

Working principle

The working principle of a spiral sand washer mainly includes the following steps:

● Feeding: Sand and gravel are fed through the inlet into the washing tank of the sand washer.

● Agitation & Washing: The spiral blades, driven by the motor, rotate to agitate the sand and gravel, causing them to tumble and mix with water flow. This process removes surface impurities and slurry.

● Grading: The cleaned sand and gravel are graded by particle size under the combined action of the spiral blades and water flow. Fine sand is discharged through the overflow port, while coarse sand exits via the discharge outlet.

● Discharge: The washed and graded sand and gravel are discharged from the outlet, completing the entire sand washing process.

Application Industries

Spiral Sand Washer finds extensive applications in the following industries:

● Construction Industry:Used for washing building-grade sand to enhance concrete quality

● Aggregate Production Lines:Serves as core sand cleaning equipment to improve market competitiveness of processed sand

● Cement Plants:Processes sand and gravel as raw materials for cement manufacturing

● Metallurgical & Chemical Industries:Handles granular material processing with efficient impurity elimination

Performance Features & Advantages:

● High-Efficiency Cleaning:

Achieves thorough impurity and slurry removal through spiral blade rotation and hydrodynamic action, delivering ≥95% cleaning purity

● Energy Conservation & Eco-Friendly:

Employs closed-loop water circulation system (water consumption ≤0.5m³/ton)

Integrates slurry separation unit for wastewater treatment (SS ≤50mg/L discharge standard)

● Simplified Maintenance Design:

Modular structure with <5% wear-prone components

Maintenance intervals extendable to 500 operational hours

● Integrated Grading Function:

Simultaneous washing and particle size classification (0.15-5mm adjustable range)

● Large-Scale Processing Capacity:

Throughput ranges 50-300 t/h (adaptable to production line configurations)

Technical Specifications Table

Equipment Model

Feed Particle Size(mm)

Processing Capacity (t/h)

Spiral Blade Diameter(mm)

Number of Spiral

(Sets)

Trough Length(mm)

Power(kw)

Overall Dimensions(mm)

LX0760

≤10

20-40

760.0

1.0

6000.0

7.5

5700X1420X1900

LX0920

≤10

30-60

920.0

1.0

8000.0

11.0

8710X1630X2080

LX1120

≤10

40-80

1120.0

1.0

8000.0

18.5

9230X1840X2130

LX1500

≤10

50-100

1500.0

1.0

8000.0

22.0

9620X2230X2480

2LX0920

≤10

60-120

920X2

2.0

8000.0

11X2

8710X2600X2080

2LX1120

≤10

80-160

1120X2

2.0

8000.0

18.5X2

9230X3050X2130

2LX1500

≤10

120-250

1500X2

2.0

8000.0

22x2

9620X3730X2480

For more detailed technical specifications or application cases, feel free to contact us for further discussion!

Previous: Wheel Sand Washer

Spiral Sand Washer

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Spiral Sand Washer

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!