Share to

Hydrocyclone cluster

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

A hydrocyclone cluster is a separation unit composed of multiple hydrocyclones arranged in parallel or series configurations. It operates on the principle of centrifugal force to achieve solid-liquid, liquid-liquid, or solid-gas separation. The core component features a conical or cylindrical chamber, typically constructed from wear-resistant materials such as alloy, polyurethane, or ceramics, making it suitable for high-wear and corrosive environments. Widely used in mining, environmental protection, chemical, and petroleum industries, it is primarily employed for processes like particle classification, concentration, de-sliming, and oil-water separation.

Working principle

1、Centrifugal Separation: The mixed material is tangentially fed into the hydrocyclone assembly under high pressure, generating a high-speed rotational flow field that creates strong centrifugal forces.

2、Density Stratification: High-density particles (or the heavy phase) are propelled toward the wall of the cyclone and descend along a helical trajectory, ultimately discharged through the underflow orifice. Meanwhile, the light phase (e.g., liquid or fine particles) migrates toward the central axis and exits via the overflow orifice.

3、Structural Influence: Separation efficiency is determined by parameters such as cyclone diameter, cone angle, inlet pressure, and others. Adjusting the dimensions of the underflow and overflow orifices allows for optimization of separation precision.Application Industries

1、Mining:

● Ore classification (e.g., ore classification in grinding circuits of concentrators)

● Tailings thickening, desliming

2、Environmental Protection:

● Sewage treatment (suspended solids removal)

● Sludge dewatering, industrial wastewater recycling

3、Chemical Industry:

● Catalyst recovery

● Liquid clarification, particle classification

4、Petroleum:

● Oil-water separation

● Drilling mud treatment

5、Others:

● Coal slurry dewatering in coal washing plants

● Sand and gravel classification in the building materials industryPerformance Features & Advantages

1、High-Efficiency Separation:

● Centrifugal acceleration up to 1,000 times gravitational force

● Wide particle size separation range (2-300 μm)

2、Modular Design:

● Flexible configuration with multi-stage hydrocyclone assemblies

● Adaptable to varying throughput capacities (single-unit capacity up to hundreds of m³/h)

3、Strong Adaptability:

● Adjustable operational parameters (e.g., pressure, orifice diameter) to accommodate variations in material concentration and particle size distribution

4、Abrasion & Corrosion Resistance:

● Internally lined with silicon carbide, rubber, ceramic, or polyurethane materialsTechnical Specifications Table

Hydrocyclone Model 10-100 (8°/10°/Multi-taper Angles)

Equipment Model

Hydrocyclone Barrel Inner Diameter(mm)

Maximum Allowable Feed Particle Size(mm)

Feed Pressure(Kpa)

Processing Capacity(m3/h)

Classification Particle Size(μm)

10

10

0.1/

100-600

0.05-0.1

1-5/

25

25

0.2/

100-600

0.3-1

5-20/

50

50

0.3/

100-400

1.5-3.5

5-40/

75

75

0.6/

100-400

3.0-7.0

10-40/

100

100

1/

100-300

9.0-18.0

20-50/

Hydrocyclone Model 125-350 (8°/10°/Multi-taper Angles)

Equipment Model

Hydrocyclone Barrel Inner Diameter(mm)

Maximum Allowable Feed Particle Size(mm)

Feed Pressure(Kpa)

Processing Capacity(m3/h)

Classification Particle Size(μm)

125

125

1/

90-300

12-24

25-50/

150

150

1.5/

80-300

16-30

20-74/

165

165

1.5/

70-300

20-40

30-74/

200

200

2/

60-300

30-50

40-100/

250

250

3/

60-300

45-70

40-100/

300

300

5/

60-200

50-85

50-150/

350

350

6/

60-200

80-130

50-150/

Hydrocyclone Model 420-840 (8°/10°/Multi-taper Angles)

Equipment Model

Hydrocyclone Barrel Inner Diameter(mm)

Maximum Allowable Feed Particle Size(mm)

Feed Pressure(Kpa)

Processing Capacity(m3/h)

Classification Particle Size(μm)

420

420

8/

60-200

100-180

74-150/

500

500

10/

40-200

180-260

74-200/

600

600

12/

40-200

200-320

74-200/

660

660

16/

30-150

260-450

74-220/

710

710

18/

30-150

320-500

74-250/

840

840

20/

30-150

450-650

74-350/

All listed parameters apply to a single hydrocyclone unit. For comprehensive technical specifications or application case studies, please feel free to contact us for further discussion!

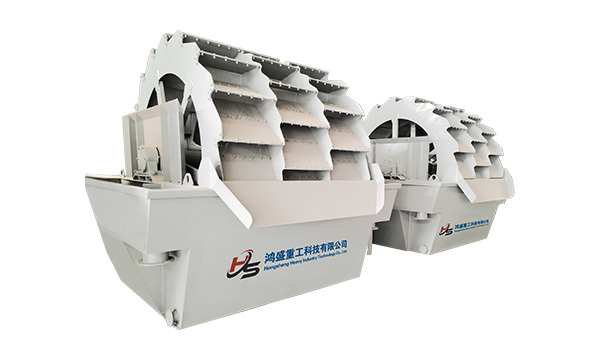

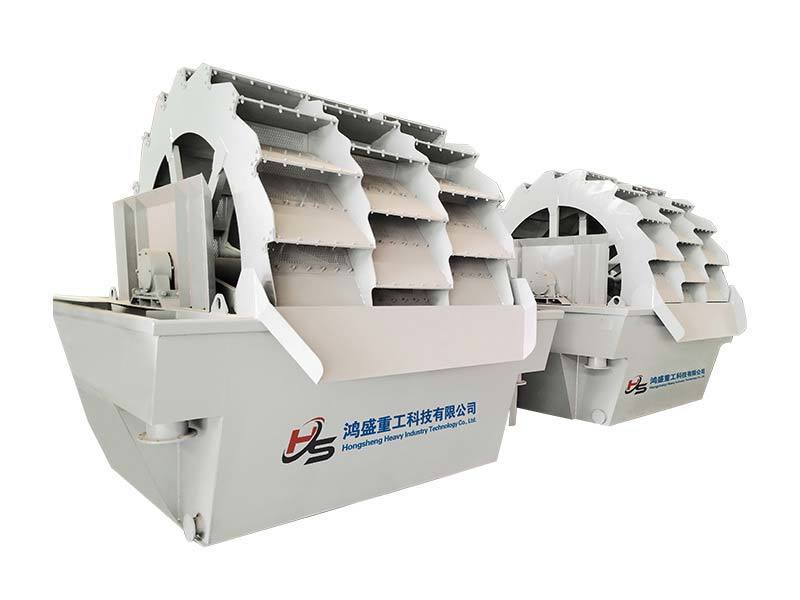

Next: Wheel-Type Integrated Sand Washing and Recycling Machine

Hydrocyclone cluster

Still deciding? Get samples first, Contact US !

Products Category

Tag list

Hydrocyclone cluster

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!