Share to

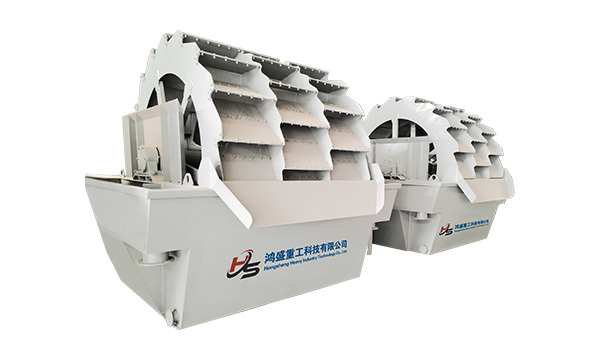

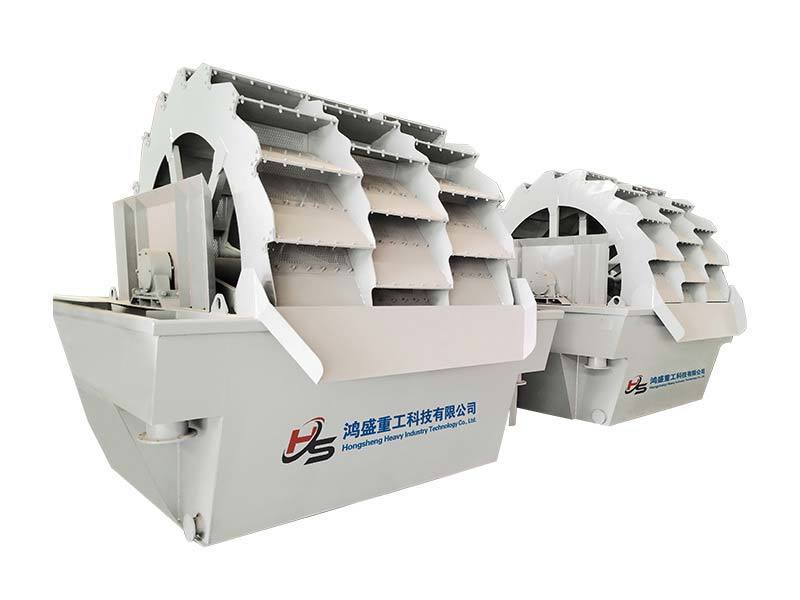

UTE integrated sand-washing and recovery machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Description

-

Product Introduction

The UTE integrated sand-washing and recovery machine is a high-efficiency sand and gravel washing equipment that combines a spiral sand washer, wheel sand washer, dual-stage fine sand recovery device, and linear dewatering screen. It is primarily used to remove soil and impurities from sand and gravel, while recovering fine sand and achieving dewatering and dry discharge. Widely applied in construction, cement, metallurgy, and chemical industries, this equipment significantly enhances sand quality through its spiral-wheel dual washing mechanism, reduces fine sand loss, lowers water consumption, and complies with environmental protection requirements.

Working principle

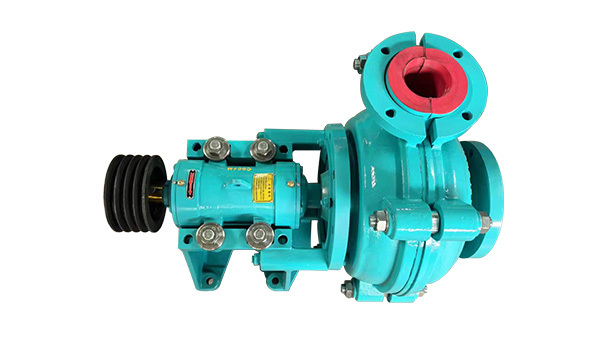

Feeding and Primary Washing:Sand and gravel enter the equipment through the feed inlet. The spiral device rotates to mix the sand/gravel with water, dissolving surface mud and impurities. Coarse particles are pushed by the spiral blades into the wheel sand washer for secondary washing. Overflow water from the tail weir flows into the first-stage recovery unit for initial fine sand recovery. The recovered fine sand re-enters the wheel sand washer for secondary washing, and the washed material then proceeds to the linear dewatering screen for classification and dehydration.

Fine sand from the overflow of the wheel sand washer and the screen underflow tank of the dewatering screen enters the second-stage fine sand recovery unit for further recovery. The recovered material is then fed into the dewatering screen to undergo dehydration alongside coarse sand before being discharged to the finished product stockpile.Application Industries

1、Construction Industry:Used for washing sand intended for concrete to enhance the quality of construction-grade sand.

2、Cement Plants:Employed to clean raw sand and gravel, ensuring the quality of raw materials for cement production.

3、Metallurgical and Chemical Industries:Utilized to process tailings sand and other granular materials, enabling efficient resource recovery.

4、Sand and Gravel Production Lines:Serves as critical equipment in production lines to improve the market competitiveness of finished sand products.Performance Features & Advantages

1. High-Efficiency Washing & Recovery

Utilizes dual washing mechanisms (spiral and wheel-based) to efficiently remove mud and impurities from sand/gravel. The two-stage fine sand recovery system minimizes resource waste.

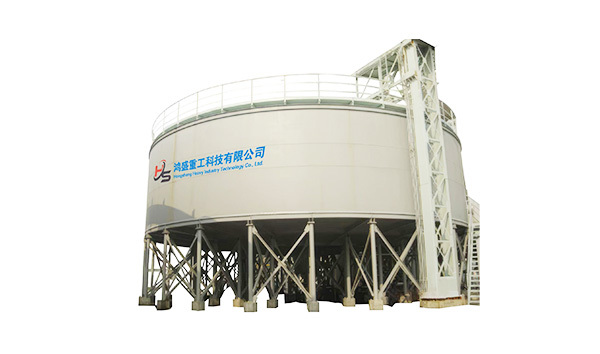

2. Energy Saving & Eco-Friendly

Features a closed-loop water circulation system to reduce water consumption, coupled with a slurry separation device to mitigate environmental pollution.

3. Robust Design & Easy Maintenance

Compact structure with low failure rates ensures simple installation, operation, and maintenance, significantly lowering operational costs.

4. High Adaptability

Adjustable settings accommodate diverse sand/gravel properties and process requirements, supporting washing and classification of multiple material types.

5. Cost-Effective Production

High processing capacity and production efficiency reduce operating costs while enhancing economic returns.

6. Why Choose the UTE Integrated Sand Washing & Recovery System?

The UTE integrated machine, renowned for its efficiency, eco-friendliness, and cost-effectiveness, has become indispensable in sand/gravel processing. It not only elevates material quality but also enables resource recycling, aligning with modern industrial demands for sustainability and productivity. For industries like construction, cement, and metallurgy, adopting the UTE system is the optimal choice to boost production efficiency and product quality.Technical Specifications Table

Equipment Model

Feed Particle Size(mm)

Processing Capacity(t/h)

Spiral Blade Diameter (mm)

Impeller Specifications (mm)

Screen Plate Specifications (mm)

Standard Two-stage Recovery Hydrocyclone Specifications(mm)

Power (kw)

Overall Dimensions (mm)

UTE-LX07-18-1224D

≤10

20-40

760

1800X800

1200X2400

300X2

44.9

11900X5250X3880

UTE-LX09-25-1530D

≤10

30-60

920

2500X1200

1500X3000

300X2

51

14550X5560X4150

UTE-LX11-30-1842D

≤10

40-80

1120

3000X1600

1800X4200

300X4

95

16250X6200X3700

UTE-2LX09-30-1842J

≤10

60-100

920X2

3000X1600

1800X4200

300X4

102.5

16250X6200X3700

UTE-2LX11-36-2442J

≤10

100-150

1120X2

3600X2000

2400X4200

350X4

140.5

17450X6800X3700

UTE-2LX15-36-3048J

≤10

120-200

1500X2

3600X2400

3000X4800

350X6

196

18000X7400X4600

UTE-2LX15-42-3660J

≤10

160-250

1500X2

4200X3000

3600X6000

350X6

214

18580X8000X5200

For more detailed technical specifications or application cases, feel free to contact us for further discussion!

Previous: Spiral Sand Washing and Recovery Integrated Machine

UTE integrated sand-washing and recovery machine

Still deciding? Get samples first, Contact US !

Products Category

Tag list

UTE integrated sand-washing and recovery machine

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!