-

-

Integrated equipment

-

Hydrocyclone cluster

-

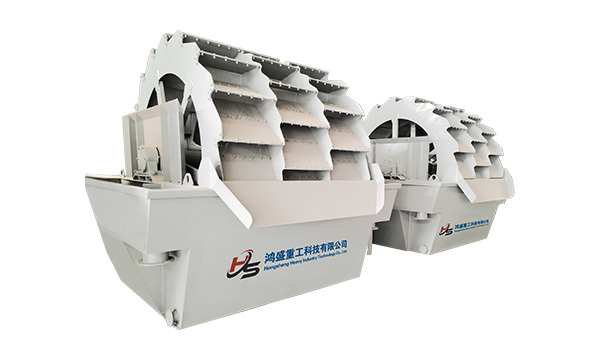

Wheel-Type Integrated Sand Washing and Recycling Machine

-

Spiral Sand Washing and Recovery Integrated Machine

-

UTE integrated sand-washing and recovery machine

View More -

-

Screening equipment

-

Shaftless Trommel Screen

-

Circular vibrating screen

-

Banana-Type Constant Thickness Screen

-

Three-axis elliptical vibrating screen

-

Linear Vibrating Screen (Dewatering/Grading Type)

-

Double layer linear sieve

-

Flip-Flow Screen

View More -

-

Cleaning equipment

View More -

Fine sand recycling equipment

View More -

Sewage treatment equipment

-

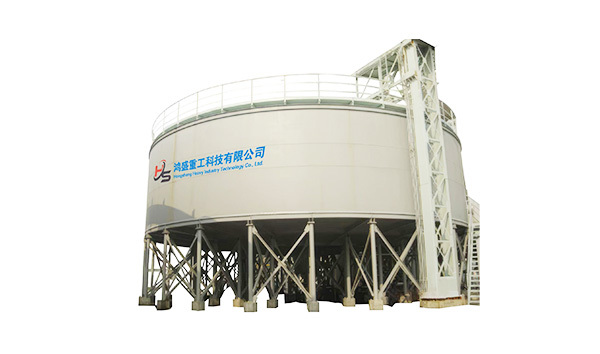

Radial Flow Thickener

-

High-Pressure Diaphragm Chamber Filter Press

-

Deep Cone Thickener

-

Chamber Filter Press

-

Belt filter press

-

Flocculant automatic dosing systems

View More -

-

Spare parts

View More

-

Quartz Sand Washing Equipment Process Selection Parameters: Building an Efficient and Clean Production System

Aug 05,2025

Processing Capacity (tons/hour): Directly determines equipment specifications and model selection.

Design maximum hourly throughput, average throughput, annual throughput.

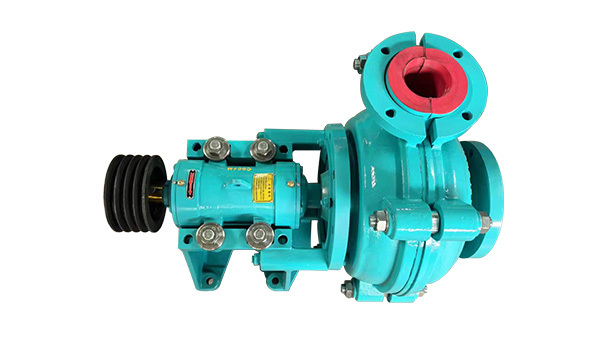

Basis for calculating equipment volume, power, and auxiliary equipment (e.g., pumps, hydrocyclones).

Requires consideration of a fluctuation factor (1.1-1.3).

Cleaning Efficiency / Product Purity Requirements: Key final product specifications, determining the number of washing stages, equipment configuration, and operational intensity.

Content of <0.075mm (or <0.063mm) particles in finished sand (%): High-end applications demand extremely low levels (<0.1% or even <0.05%).

Maximum allowable content of specific impurities: Fe₂O₃, Al₂O₃, mica, etc.

Implication: Higher purity requirements necessitate more intensive processes: high-intensity attrition scrubbing + efficient multi-stage desliming (e.g., multi-stage hydrocyclones) + precise classification, and potentially chemical cleaning.

Product Moisture Content Requirement: Impacts drying costs and subsequent transportation/storage.

Maximum allowable moisture content (%) in finished sand.

Determines the selection of dewatering equipment (e.g., dewatering screens, dewatering hydrocyclones, filter presses, dryers) and their required efficiency.

Hot Tags:

Contact Us

E-mail:info@hszgtech.cn

WhatsApp:+86 19838996250

Tel:+8619838996250

Tel:+8618625415217

Address: North end of Hong Kong Road, Xiaoji Town, Xinxiang County, Xinxiang City, Henan Province

REQUEST QUOTE

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页