-

-

Integrated equipment

-

Hydrocyclone cluster

-

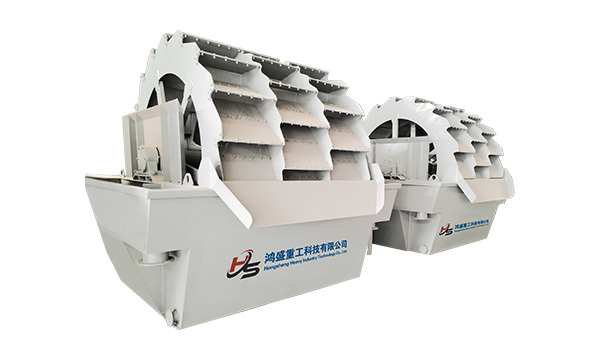

Wheel-Type Integrated Sand Washing and Recycling Machine

-

Spiral Sand Washing and Recovery Integrated Machine

-

UTE integrated sand-washing and recovery machine

View More -

-

Screening equipment

-

Shaftless Trommel Screen

-

Circular vibrating screen

-

Banana-Type Constant Thickness Screen

-

Three-axis elliptical vibrating screen

-

Linear Vibrating Screen (Dewatering/Grading Type)

-

Double layer linear sieve

-

Flip-Flow Screen

View More -

-

Cleaning equipment

View More -

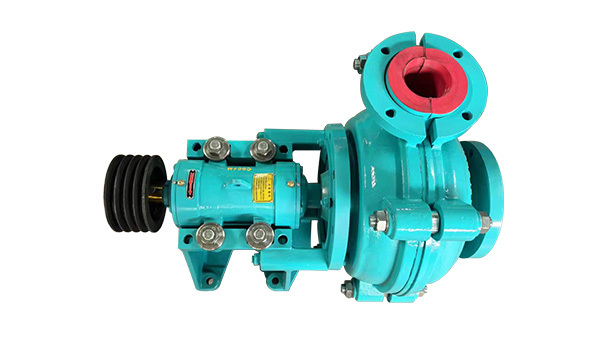

Fine sand recycling equipment

View More -

Sewage treatment equipment

-

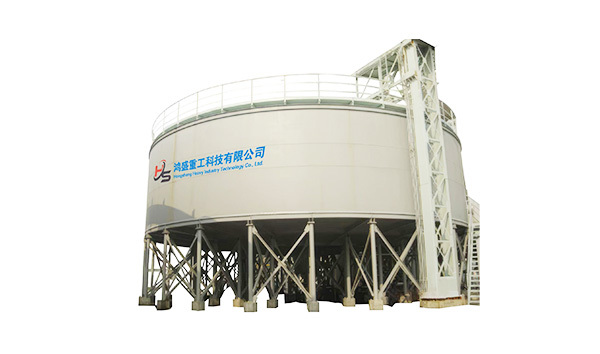

Radial Flow Thickener

-

High-Pressure Diaphragm Chamber Filter Press

-

Deep Cone Thickener

-

Chamber Filter Press

-

Belt filter press

-

Flocculant automatic dosing systems

View More -

-

Spare parts

View More

-

Vibrating Screen Box-Type Exciter: The Core Driving Force - Powerful, Reliable, and Efficient

Jun 27,2025

Box-type exciters have become the preferred drive solution for modern medium-to-large and heavy-duty vibrating screens, owing to their unique design and superior performance. They not only safeguard stable equipment operation but are also pivotal in enhancing screening efficiency while reducing maintenance costs.

Core Advantages of Box-Type Exciters

Exceptional Load Capacity: Withstands massive dynamic and impact loads, effectively counteracting screen body deformation effects on the exciter, significantly enhancing overall equipment lifespan and stability.

Advanced Sealing Protection: Multi-stage sealing design effectively isolates ingress of external contaminants (dust, moisture), safeguarding critical bearings.

Optimized Lubrication & Cooling: Typically equipped with an oil lubrication station, ensuring continuous, adequate, and reliable lubrication and cooling. This significantly reduces bearing operating temperatures and minimizes wear.

Extended Bearing Life & Reduced Maintenance: Achieves multiplied bearing lifespan and substantially increased maintenance intervals, drastically reducing downtime and maintenance costs.

Robust Synchronized Force Generation: Utilizes two or four eccentric shafts (with counterweights). Force synchronization is achieved via gears or cardan shafts (forced synchronization) or through self-synchronizing design, generating powerful directional excitation force.

High-Capacity, Stable Output: Delivers massive, stable, and reliable vibration force. Provides robust power for screening equipment handling heavy loads and large particle sizes, ensuring high screening efficiency and effectiveness.

Operational Excellence: Smooth operation with lower noise levels. Features simplified installation and optimized force distribution.

The box-type exciter, characterized by its robust housing structure, unparalleled reliability, durability, and powerful output, directly addresses the critical pain points of vibrating screens operating under harsh conditions (heavy load, dusty, humid, continuous operation) – namely short bearing life, high failure rates, and frequent maintenance. Through precision mechanical design and advanced lubrication/sealing technology, it becomes the essential core component guaranteeing long-term, high-efficiency, and low-cost operation of vibrating screens.

Hot Tags:

PREVIOUS:

Contact Us

E-mail:info@hszgtech.cn

WhatsApp:+86 19838996250

Tel:+8619838996250

Tel:+8618625415217

Address: North end of Hong Kong Road, Xiaoji Town, Xinxiang County, Xinxiang City, Henan Province

REQUEST QUOTE

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页