-

-

Integrated equipment

-

Hydrocyclone cluster

-

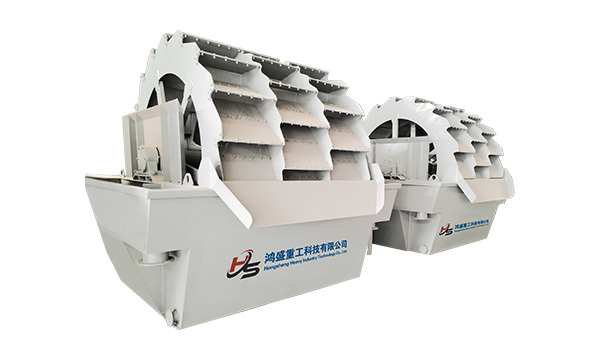

Wheel-Type Integrated Sand Washing and Recycling Machine

-

Spiral Sand Washing and Recovery Integrated Machine

-

UTE integrated sand-washing and recovery machine

View More -

-

Screening equipment

-

Shaftless Trommel Screen

-

Circular vibrating screen

-

Banana-Type Constant Thickness Screen

-

Three-axis elliptical vibrating screen

-

Linear Vibrating Screen (Dewatering/Grading Type)

-

Double layer linear sieve

-

Flip-Flow Screen

View More -

-

Cleaning equipment

View More -

Fine sand recycling equipment

View More -

Sewage treatment equipment

-

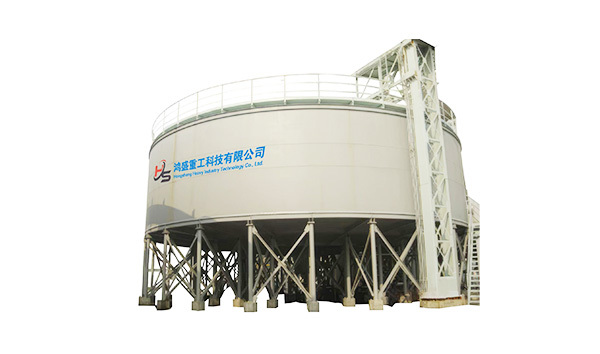

Radial Flow Thickener

-

High-Pressure Diaphragm Chamber Filter Press

-

Deep Cone Thickener

-

Chamber Filter Press

-

Belt filter press

-

Flocculant automatic dosing systems

View More -

-

Spare parts

View More

-

Material Selection Advantage Analysis in Linear Screens, Banana Screens, and Flip-Flow Screens

Jun 17,2025

In the design and manufacturing of critical screening equipment – includingLinear Screens, Banana Screens (Constant-Bed-Thickness Screens), and Flip-Flow Screens (Tensioned Screens)– the choice of structural steel directly impacts equipment performance, service life, and operational safety. This analysis examines the core distinctions and respective advantages of Q345B and Q345D steels to inform professional material selection decisions.

Q345B Advantages:Enhanced Strength and Ambient Toughness:Demonstrates superior strength and room-temperature impact toughness compared to standard carbon steels.

Increased Load Capacity and Structural Rigidity:Improves load-bearing capability while enhancing structural stiffness.

Primary Material for Core Structures:The preferred choice for main structural components in most screening equipment (e.g., screen frames, side plates, cross beams, vibrator mounting bases).

Optimal for Standard Conditions:Particularly suitable for operation in ambient temperatures or non-arctic environments.

Q345D Advantages:Exceptional Low-Temperature Toughness:Ensures reliable operation in low-temperature environments (down to -20°C), mitigating brittle fracture risks.

Optimized Strength-Toughness Balance:Maintains the high-strength characteristics of the Q345 series while providing superior toughness reserve.

Critical Material for Demanding Service:Essential for enhancing equipment durability and safety margins under severe operating conditions.

Q345D Application Scenarios:Outdoor installations in arctic regions、Equipment processing low-temperature materials

Safety-critical load-bearing components (e.g., main beams, vibration transfer structures in large screens)

Material Selection Recommendations:

For core structural elements (screen frames, vibrating beams) across all screen types:

Prioritize the Q345 seriesover standard carbon steels

Grade selection (B/D) primarily depends on minimum operating temperature

Q345D is mandatoryfor:Arctic installations

Low-temperature material processing/dewatering

Applications requiring maximum safety assurance

Critical Operational Consideration:

In northern arctic regions or when handling cold materials,investment in Q345D delivers significant safety returns and extended service life by preventing catastrophic brittle fractures and associated production losses.The fundamental safety contribution of low-temperature toughness must never be compromised by initial material cost considerations.

Hot Tags:

Contact Us

E-mail:info@hszgtech.cn

WhatsApp:+86 19838996250

Tel:+8619838996250

Tel:+8618625415217

Address: North end of Hong Kong Road, Xiaoji Town, Xinxiang County, Xinxiang City, Henan Province

REQUEST QUOTE

We will contact you within one working day. Please pay attention to your email.

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页